Adhesive agent for thermal insulation material and surface coating material

TOMBO™ No. 9861/9871

FA ADHESIVE/SPRAY COAT

The adhesive is used as an adhesive for various linings. There are three types available that are distinguished by the base material: FF adhesive, FC adhesive, and FM adhesive.

The spray coat (surface coating material) was developed as a surface coating material for various linings. By spraying about 1 to 2 mm onto a surface, it offers improved windspeed resistance, scale resistance, dust resistance, and alkali resistance.

*Be aware that the adhesive performance of the coating material may drop according to the usage environment.

Product Category

Thermal Insulation MaterialUp to 600°CUp to 1500℃

Industry

Carbon Neutrality and DecarbonizationIndustrial-Use InsulationVarious Plant FacilitiesIndustrial Furnaces (Electric Furnaces/Combustion Furnaces)

Forte

It stores little heat and so can reduce the heat storage loss on furnace walls.

It offers excellent thermal shock resistance.

It offers excellent chemical stability.

The product is lightweight and so it is easy to handle.

Application

Adhesion of various linings

Spray coat (surface coating material)

Surface coating of various linings

Quality characteristics

The following adhesives are used according to the base material to adhere various linings.

| Type | Base material | Color and shape | Maximum heat resistant temperature (°C) Note 2 | Density (g/cm3) Note 3 | Non-volatile component (%) | Chemical components (%) | Amount required for installation location (kg/m2) | Quantity per can | ||

|---|---|---|---|---|---|---|---|---|---|---|

| FF adhesive | ・ FINEFLEX BIO ・ Alumina fiber |

White paste | 1700 | 1.8 | 61 | Al2O3 :86 SiO2 :13 |

1.0 to 1.5 | 330 cc (cartridge) 5kg, 25kg |

||

| FC adhesive | General furnace walls | Gray paste | 1400 | 1.8 | 70 | Al2O3 :55 SiO2 :41 |

7 to 10 | 3kg 25kg |

||

| FM adhesiveNote 1 | Steel plate | Black paste | 600 | 3.1 | 85 | Fe :80 SiO2 :13 |

3 to 5 | 3kg set 25kg set |

||

Note 2: The maximum heat resistance temperature of the adhesive.

When using it for FINEFLEX BIO, please be aware that the bonding effect may decrease or a melting reaction may occur at temperatures above 1, 100°C.

Note 3: This is the density before drying (paste form).

Spray coat (surface coating material)

| Base material | Color and shape | Maximum heat-resistant temperature (°C)Note 1 |

Density (kg/m3) Note 2 |

Chemical components (%) |

Required amount at installation location (kg/m2) |

Quantity per can | ||

|---|---|---|---|---|---|---|---|---|

| Type | Spray Coat | FINEFLEX BIO | Gray Paste |

1500 | 2500 | ZrO2:50 SiO2:30 SiC:4 |

3 to 5 (Thickness: 1 to 2 mm) |

5kg, 20kg |

| Spray coat FA | Alumina fiber | Light blue Paste |

1500 | 1200 | AI2O3:94 SiO2:6 |

4 to 5 (Thickness: 1 to 2 mm) |

20kg |

When using it to coat the surface of FINEFLEX BIO, please be aware that the bonding effect of the coating material may decrease or a melting reaction may occur at temperatures above 1, 100°C.

Note 2: This is the density before drying (paste form).

*The values above are our actual measurement values. They are not standard values.

*The storage period is 6 months when storing in a sealed dark indoor environment that is 4°C or more.

*Be aware that the adhesive performance of the coating material may drop according to the usage environment.

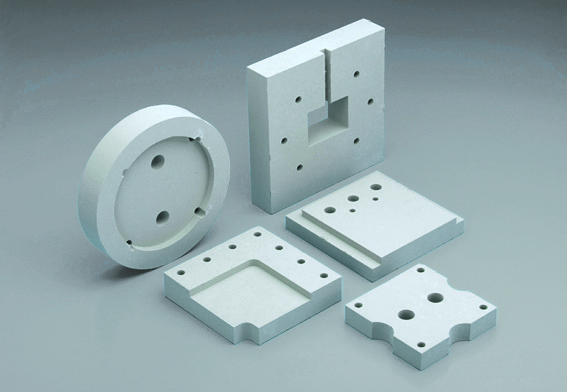

Product appearance

Spray Coat

Other

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.