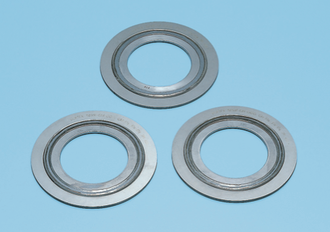

Spiral wound gasket with composite filler for high-temperature use

VORTEX™ GASKET

TOMBO™ No. 1806-GH

The VORTEX GASKET is a gasket that can be used in high-temperature conditions of 450°C or more by combining expansion graphite (GRASEAL) tape, which mixes antioxidant with filler material, with an oxygen barrier (mica layer) to prevent the GRASEAL oxidizing at high temperatures.

It is suitable for high-temperature conditions of 650°C or more.

Spiral wound gaskets with expanded graphite filler (for low temperatures and low surface pressure sealant)

VORTEX™ GASKET

TOMBO™ No. 1839R

It is a gasket with a large amount of filler outside the sealed surface and that enables a seal with less clamping force than regular GRASEAL™ and VORTEX™ gaskets.

It can also be used for low-temperature production lines such as liquefied natural gas (LNG), liquid nitrogen (LN2), and liquefied air.

Super high temperature filler spiral wound gasket

VORTEX™ gasket ‒NM (Basic Type)

TOMBO™ No. 1808-NM

It is a new gasket that can be used even in areas over 450°C by using high-temperature fillers developed by our company.

Almost no loss of filler by oxidation is observed at high temperatures and stable sealability is maintained for a long time.

In addition, fluids that oxidize and dissipate expanded graphite such as molten salts can also be used without issues.

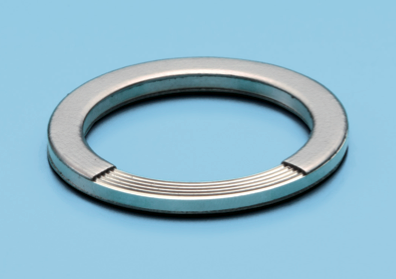

Grooved semi-metallic gasket

KAMMPROFILE GASKET

TOMBO™ No. 1891-GR

It can be used under strict thermal cycle conditions, and as the load is concentrated on the serrated edges, it also demonstrates excellent sealing performance at low clamping forces.

An inner ring to prevent buckling is not needed and so it can be designed to have a narrow gasket width.

It will not come loose even when used for large diameters.

It is suitable for parts where the width of the equipment, such as heat exchangers and pressure containers, and flange seats is narrow and a VORTEX GASKET cannot be used.

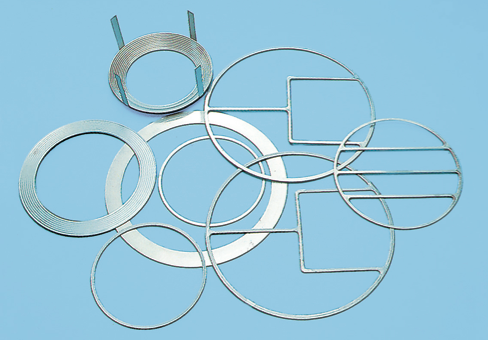

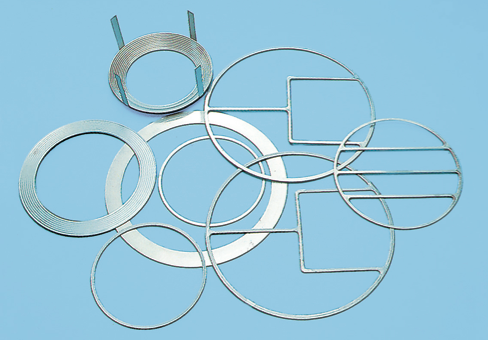

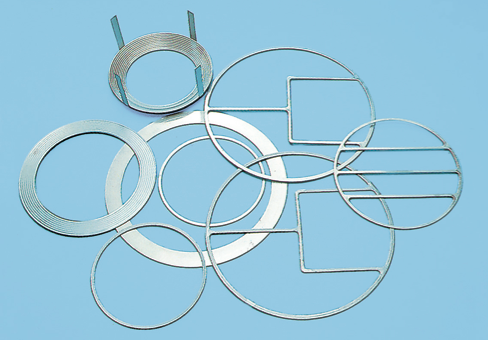

Metal jacketed gasket

METAL JACKETED GASKET

TOMBO™ No. 1841

It is possible to manufacture various shapes, such as those with branches, to suit the application and where the product will be installed.

It is used for heat exchanges, pressure containers, tower tanks, equipment, valves, high-temperature joint flanges, manholes, etc.

Metal jacketed gasket

METAL JACKETED GASKET

TOMBO™ No. 1841-FI

It is possible to manufacture various shapes, such as those with branches, to suit the application and where the product will be installed.

As it is made of a heat-resistant core material, it is used for high-temperature heat exchangers, pressure containers, tower tanks, equipment, valves, joint flanges, manholes, etc.

Metal jacketed gasket

METAL JACKETED GASKET

TOMBO™ No. 1861

It is possible to manufacture various shapes, such as those with branches, to suit the application and where the product will be installed.

It is used for heat exchanges, pressure containers, tower tanks, equipment, valves, high-temperature joint flanges, manholes, etc.

Metal jacketed gasket

METAL JACKETED GASKET

TOMBO™ No. 1861-FI

It is possible to manufacture various shapes, such as those with branches, to suit the application and where the product will be installed.

As it is made of a heat-resistant cushioning material, it is used for high-temperature heat exchangers, pressure containers, tower tanks, equipment, valves, joint flanges, manholes, etc.

other packing

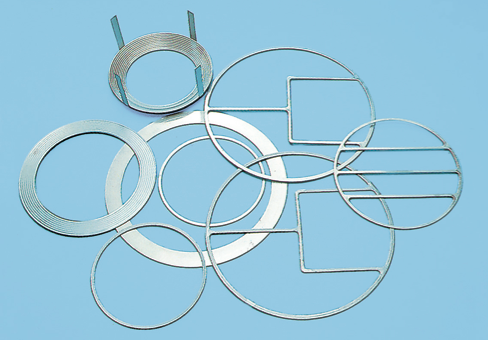

OCT RING JOINT GASKET

TOMBO™ No. 1850C

The Ring Joint Gasket is a gasket processed into specific shapes by machining cast metal materials. It is used for high-temperature, high-pressure pipe flanges, valves, pressure containers, and heat exchangers.

OCT RING JOINT GASKET is a gasket that offers sealing properties by having the sealed surface and the flange grooves engage in surface-to-surface contact. If carrying out sliding work, the gasket can be reused (providing the sealed surface is in good condition).

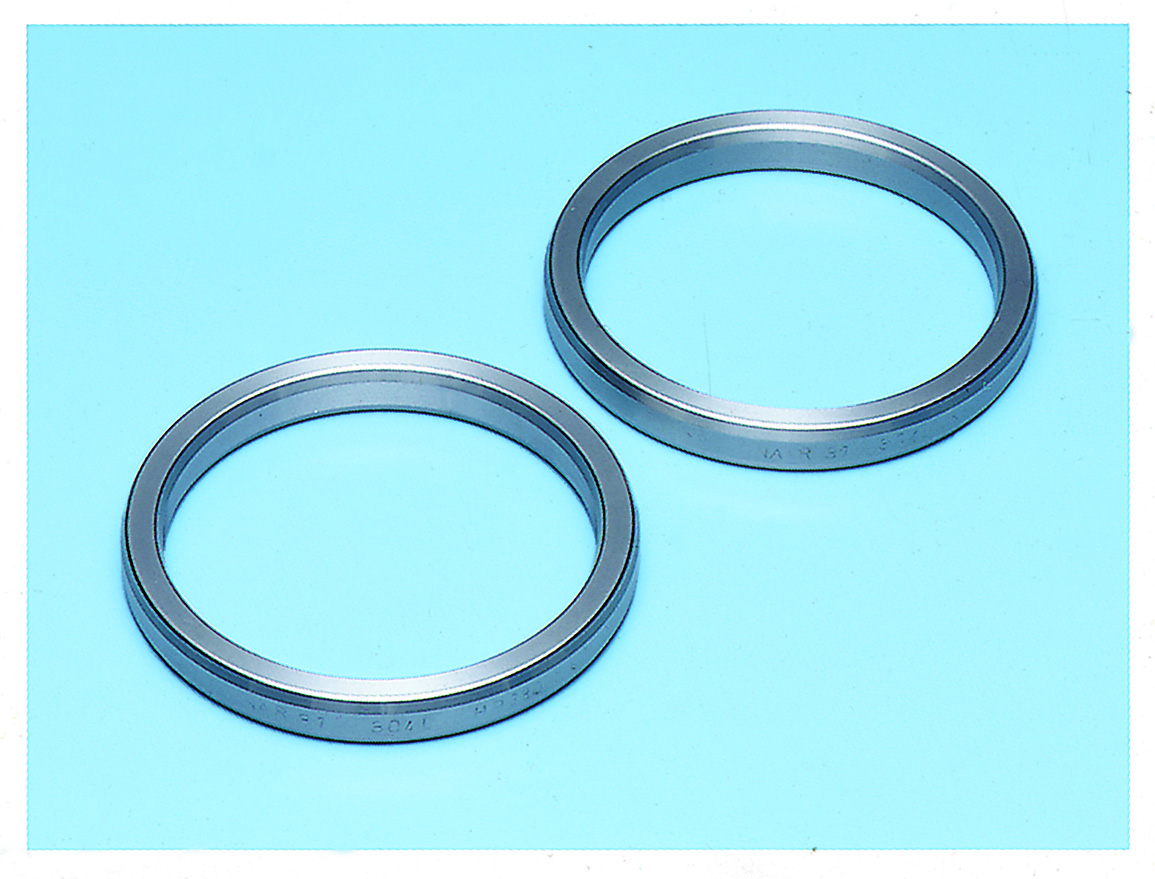

OVAL RING JOINT GASKET

OVAL RING JOINT GASKET

TOMBO™ No. 1850V

The Ring Joint Gasket is a gasket processed into specific shapes by machining cast metal materials. It is used for high-temperature, high-pressure pipe flanges, valves, pressure containers, and heat exchangers.

With its oval shape, the sealed surface forms a linear contact and so it adapts easily to the flange grooves. On the other hand, the ring cannot be reused.

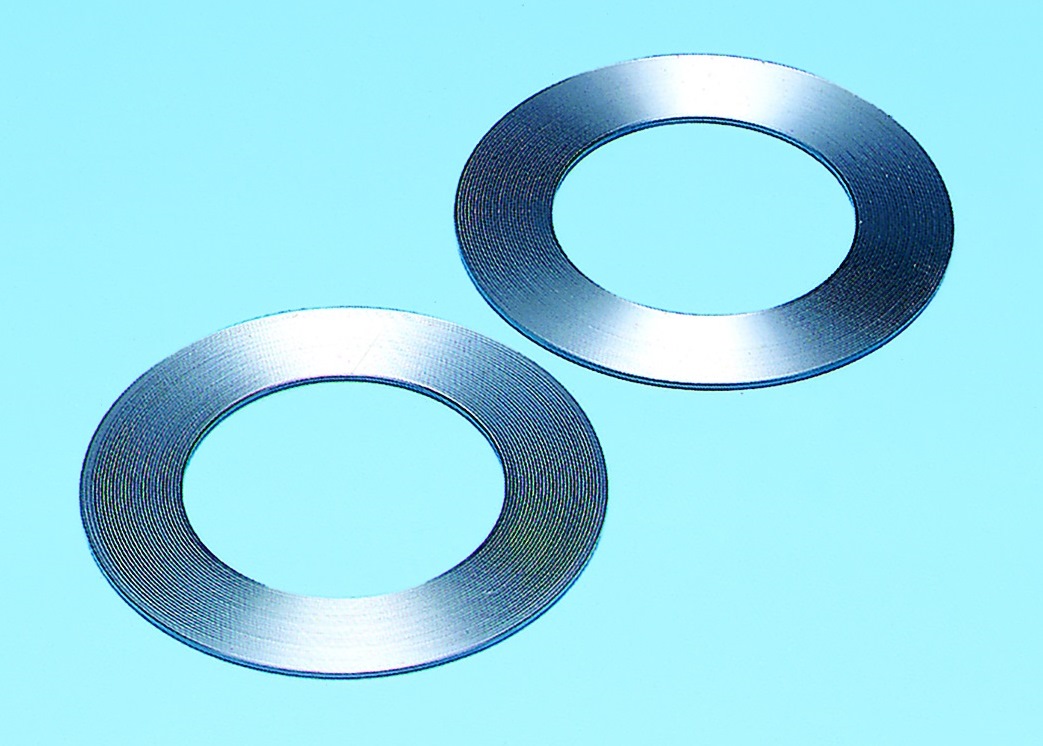

Metal solid gasket (serrated)

SERRATED METALLIC GASKET

TOMBO™ No. 1890

Its shape gives it excellent sealing properties compared to flat metal gaskets.

Although it is subject to concentrated surface pressure, the flange surface may get scratched.

It is a gasket used for pipe flanges, valves, pressure containers, and heat exchangers.

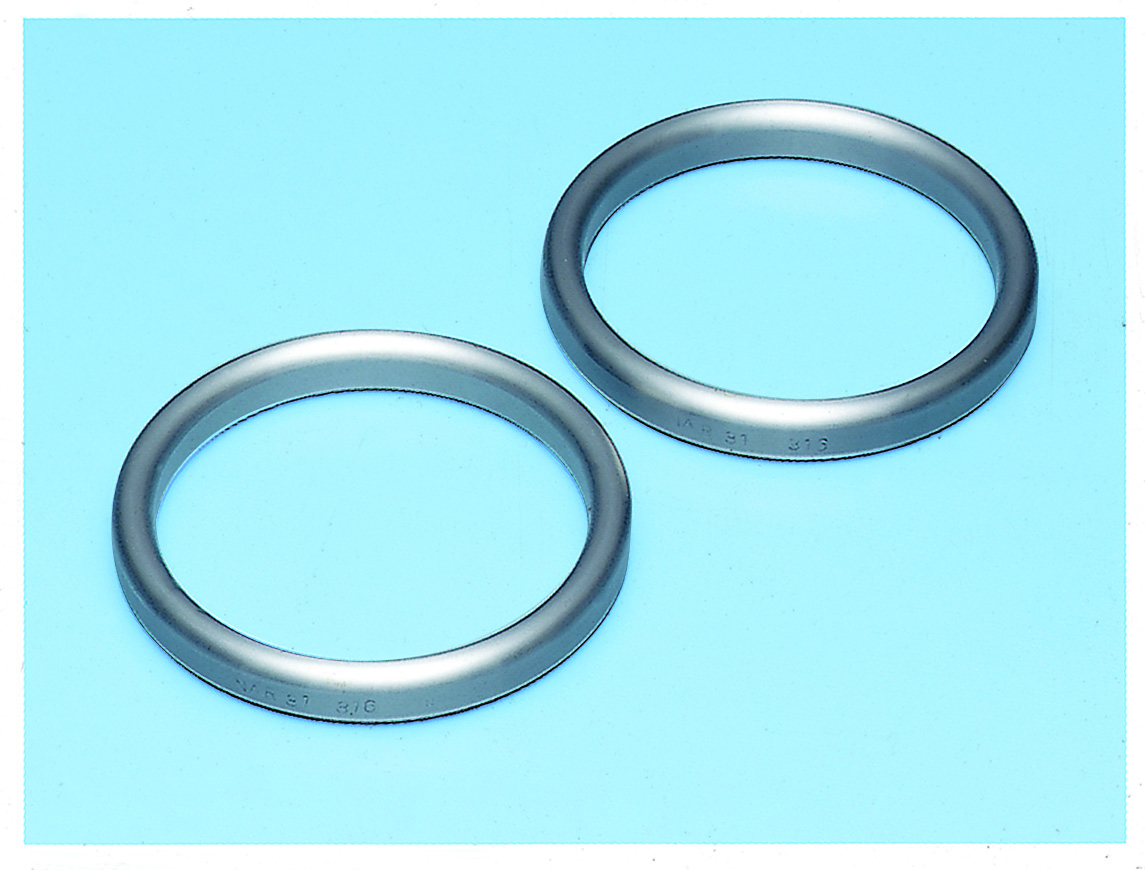

Hollow metal ring

METAL O-SEAL

TOMBO™ No. 9200P

A gasket made by molding thin metal piping into the shape of an O-ring, welding it at the ends, and then subjecting the surface to ultra-precision finishing. This gasket provides a very reliable, top-class seal across a wide range of conditions from high temperatures to low temperatures and high pressure to vacuum states.

It is used by fitting it onto the grooves and fully clamping it to enable a high-pressure seal with little clamping force.

If the internal pressure is 7 MPa or more, please use TOMBO No.9200V (model with holes).

In the case of gaseous fluids, vacuumed fluids, and highly volatile fluids, Nichias recommends its PTFE coating or silver plating specifications.

It is used for various applications such as valve bonnets, high-pressure container flanges, equipment joints, pipe flanges, plastic processing machinery, rubber extruders, hydraulic equipment, air pressure equipment, vacuum equipment, nuclear vessels, aircraft engines, rocket engines, and automobile engines.