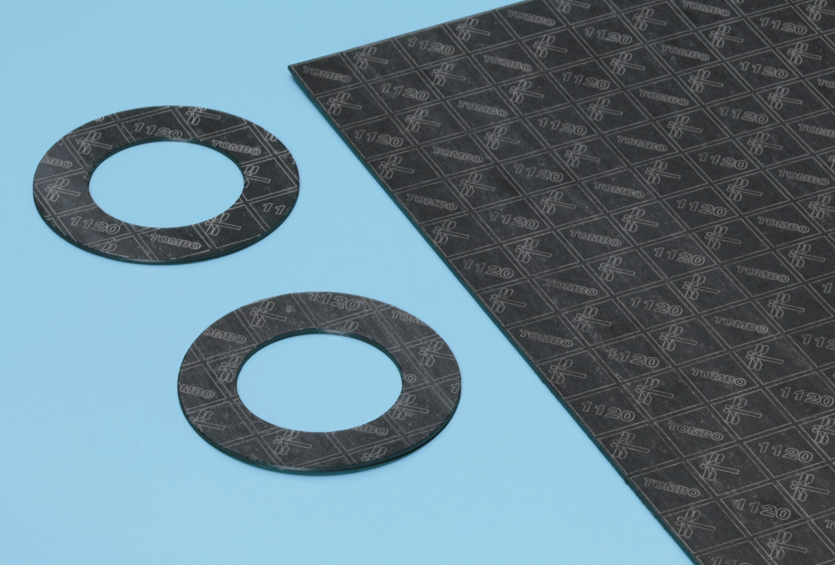

Joint sheet

CLINSIL™ Top

TOMBO™ No. 1120

Expanded graphite is its main material, and so it has excellent heat resistance, steam resistance, and corrosion resistance.

It is not susceptible to scratches and has excellent flexibility.

It is used for flanges, valves, and equipment in comparatively hot temperatures.

For low-temperature fluids such as liquefied natural gas (LNG), Nichias recommends TOMBO No.1120-LN, which undergoes special treatment.

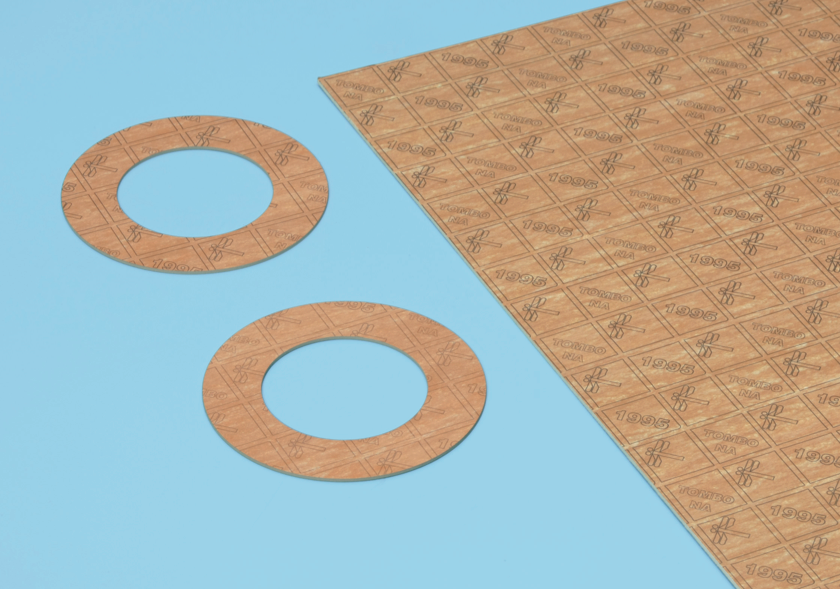

Joint sheet

CLINSIL™ Brown

TOMBO™ No. 1995

It is a standard grade joint sheet.

Nichias can manufacture large-diameter gaskets without joints at a maximum size of 3810 × 3810 mm (9S size).

It is used for flanges, valves, and equipment in comparatively low temperatures.

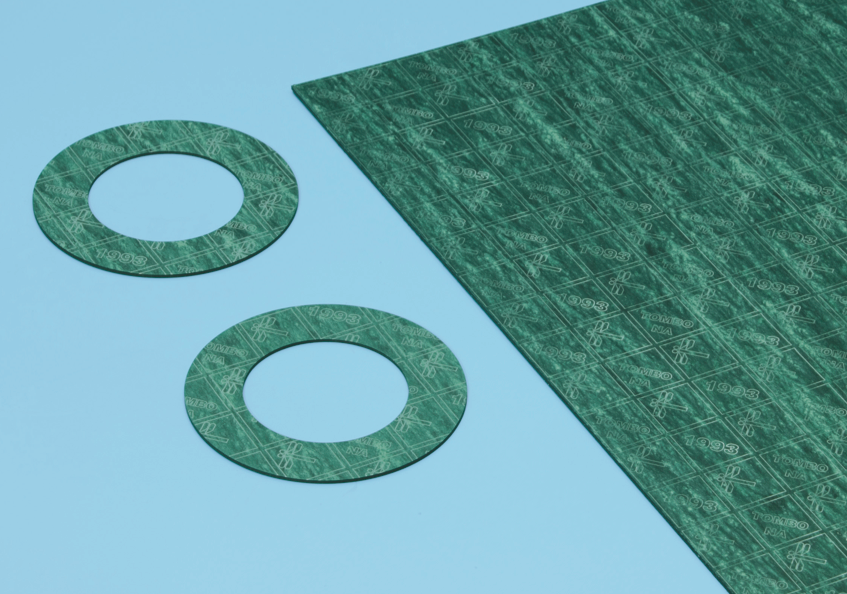

Joint sheet

CLINSIL™ Super

TOMBO™ No. 1993

It has excellent heat resistance and steam resistance and is suitable for steam lines.

Spiral wound gaskets with expanded graphite filler (for low temperatures and low surface pressure sealant)

VORTEX™ GASKET

TOMBO™ No. 1839R

It is a gasket with a large amount of filler outside the sealed surface and that enables a seal with less clamping force than regular GRASEAL™ and VORTEX™ gaskets.

It can also be used for low-temperature production lines such as liquefied natural gas (LNG), liquid nitrogen (LN2), and liquefied air.

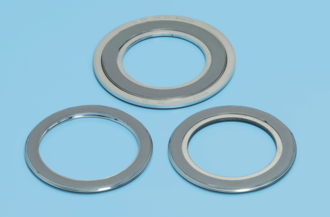

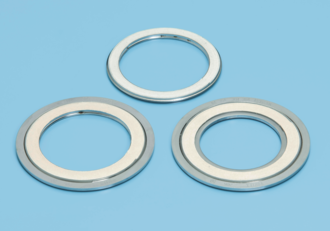

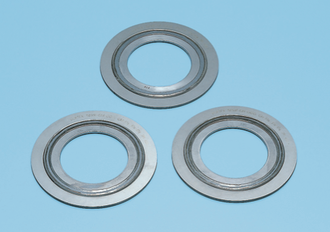

Spiral wound gasket with expanded graphite filler

VORTEX™ GASKET

TOMBO™ No. 1804-GR

It demonstrates excellent sealing performance even in strict conditions such as high temperatures and high pressures, ultra-low temperatures, and thermal cycles.

It offers better sealing performance than NA VORTEX GASKET (particularly sealing against gas).

As it has excellent corrosion resistance, it can be used for corrosive fluids if you choose an appropriate hoop material.

It has excellent sealing performance at low-temperature conditions.

It is a gasket that is particularly suitable for high-temperature and high-pressure steam applications such as pipe flanges, valves, pressure containers, heat exchangers, and valve bonnets of various industries, as well as low-temperature applications like liquefied natural gas (LNG).

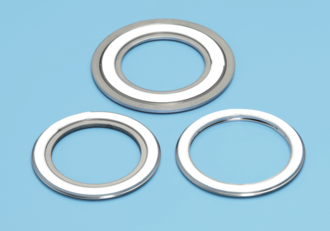

Spiral wound gasket with NA paper filler

VORTEX™ GASKET

TOMBO™ No. 1804-NA

A cost-effective VORTEX GASKET that uses NA paper as a filler.

It is suitable for parts where you want to avoid black filler.

It is used for pipe flanges, pressure containers, heat exchangers, and valve bonnets of various industries.

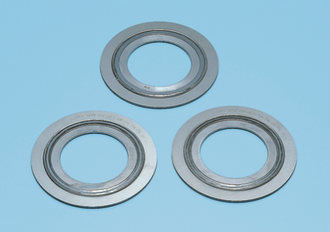

Spiral wound gasket made of fluororesin filler

VORTEX™ GASKET

TOMBO™ No. 9090

Because it uses PTFE with excellent chemical resistance as a filler, it can be used for almost all fluids if you choose an appropriate hoop material.

It is one of the best VORTEX gaskets in terms of sealing performance, and it can also be used for vacuum applications.

It is used for pipe flanges, pressure containers, heat exchanges, and valve bonnets from various industries. It is suitable for sealing against corrosive fluids and oxygen that other VORTEX products cannot be used for, parts that especially require airtightness, and vacuum sealing.

For applications using pure liquid oxygen, Nichias also offers an OX type that removes PTFE oil components.

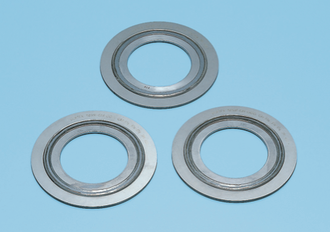

Spiral wound gasket with composite filler for high-temperature use

VORTEX™ GASKET

TOMBO™ No. 1806-GS

The VORTEX GASKET is a gasket that can be used in high-temperature conditions of 450°C or more by combining expansion graphite (GRASEAL) tape, which mixes antioxidant with filler material, with an oxygen barrier (mica layer) to prevent the GRASEAL oxidizing at high temperatures.

It is suitable for parts where oxygen is not included in the internal fluid.

Spiral wound gasket with composite filler for high-temperature use

VORTEX™ GASKET

TOMBO™ No. 1806-GM

The VORTEX GASKET is a gasket that can be used in high-temperature conditions of 450°C or more by combining expansion graphite (GRASEAL) tape, which mixes antioxidant with filler material, with an oxygen barrier (mica layer) to prevent the GRASEAL oxidizing at high temperatures.

If the working temperature is 450°C or less, Nichias recommends a regular VORTEX gasket.

Spiral wound gasket with composite filler for high-temperature use

VORTEX™ GASKET

TOMBO™ No. 1806-GH

The VORTEX GASKET is a gasket that can be used in high-temperature conditions of 450°C or more by combining expansion graphite (GRASEAL) tape, which mixes antioxidant with filler material, with an oxygen barrier (mica layer) to prevent the GRASEAL oxidizing at high temperatures.

It is suitable for high-temperature conditions of 650°C or more.

Spiral wound gaskets with expanded graphite filler (for low temperatures and low surface pressure sealant)

VORTEX™ GASKET

TOMBO™ No. 1839R

It is a gasket with a large amount of filler outside the sealed surface and that enables a seal with less clamping force than regular GRASEAL™ and VORTEX™ gaskets.

It can also be used for low-temperature production lines such as liquefied natural gas (LNG), liquid nitrogen (LN2), and liquefied air.

Super high temperature filler spiral wound gasket

VORTEX™ gasket ‒NM (Basic Type)

TOMBO™ No. 1808-NM

It is a new gasket that can be used even in areas over 450°C by using high-temperature fillers developed by our company.

Almost no loss of filler by oxidation is observed at high temperatures and stable sealability is maintained for a long time.

In addition, fluids that oxidize and dissipate expanded graphite such as molten salts can also be used without issues.