Hot and Cold Insulation Work

Example of thermal insulation (heat/cold insulation) work

This page introduces some examples of Nichias’ thermal insulation (heat/cold insulation) work.

Hot insulation work

Aerogel™ heat-insulation work

Aerogel heat-insulation material Pyrogel XTE is a thermal insulation material with low thermal conductivity and excellent water repellency and flexibility. Nichias has developed an innovative construction method that takes advantage of its excellent performance to contribute to the conservation of Planet Earth.

Cold insulation work for LNG carriers

Cold insulation work for LNG carriers

LNG (liquefied natural gas) vessels, which are used to transport LNG to consumer destinations, require advanced heat-protection performance and strength.

Nichias supplies its customers by acquiring certification from a ship classification society for its various thermal insulating materials for LNG carriers, which include its environment-friendly, CFC-free glass fiber reinforced urethane foam that satisfies these performance requirements. Nichias also carries out the installation work of these materials to guarantee installation is done correctly.

Sound-proofing work (power stations and plants, etc.)

Acoustic insulation work

Nichias has an excellent track record of soundproofing work at power stations, chemical plants, waste incineration facilities, and other business establishments in various fields.

In addition to its many excellent soundproofing materials, with experience and a track record dating back over 40 years, Nichias meets a variety of customer demands relating to measures to tackle noise with its comprehensive system of measuring noise, providing consultations, designing, installing, and checking the benefits of its noise measures.

Heat-insulation material for cryogenic pipes

FOAMNERT™ SUPPORT

TOMBO™ No. 5010

TOMBO No.5010 FOAMNERT SUPPORT is a low-temperature pipe support with excellent thermal insulation and mechanical strength developed from Nichias’ testing of urethane foam technologies and cryogenic installation technologies as a manufacturer of thermal and cryogenic insulation materials.

FOAMNERT SUPPORT has a base of high-density urethane foam, and so in addition to its strength as a structural material, it has outstanding thermal insulation and weather resistance.

Stack lining maintenance work

Stack lining maintenance work

In a broad range of fields that include the likes of waste incinerators, petrochemical plants, and industrial furnaces, Nichias uses its vast experience and advanced technologies that it has developed over the years to carry out efficient stack lining work in material development, design, installation, and maintenance that meet the needs of its customers.

Cryogenic insulation material (urethane-based)

Cryogenic insulation material (urethane-based)

In terms of clean energy, Nichias is engaged in a large amount of cold insulation work from liquefaction facilities to transportation, receiving, and storage facilities as a cold insulation work pioneer in the fields of liquefied natural gas (LNG) and liquefied petroleum gas (LPG) that are growing in demand. FOAMNERT TN is a pioneering cryogenic insulation material made of rigid carbonated urethane foam that uses no Freon blowing agents. As a cryogenic insulation material with little burden on the environment and maintains the thermal insulation performance of products to date, it continues to win the hearts of more and more customers.

Nichias strives to extend the lifespan of facilities with its efforts to diagnose the thermal insulation performance of cryogenic insulation materials and renovation efforts for cryogenic insulation materials to recover the thermal insulation performance without shutting down the facility.

Nuclear power-related work

Nuclear power-related work

Nichias actively engages in heat-insulation work and radioactivity shielding work for nuclear power facilities and provides the quality required to meet its customers’ demands.

Furnace lining work

Furnace lining work

In a broad range of fields that include the likes of waste incinerators, petrochemical plants, and industrial furnaces, Nichias uses its vast experience and advanced technologies that it has developed over the years to carry out efficient fireproofing and furnace lining work in material development, design, installation, and maintenance that meet the needs of its customers.

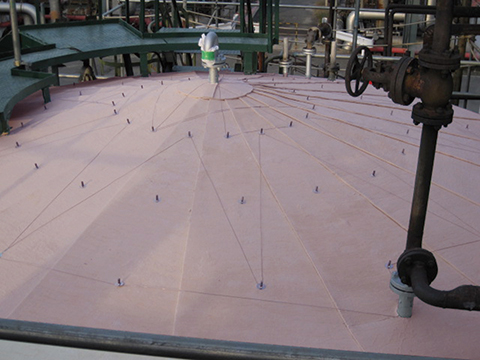

Electric heater tracing work

Electric heater tracing work

Food, pharmaceutical, and fine chemical plants require precise temperature control of internal fluids, which are the raw materials.

Electric heater tracing is an electric control system that uses self-regulating and mineral-insulated (MI) heater cables. It can be made to match the insulation design and installation and keep the temperature of the corresponding equipment to a predetermined temperature. Furthermore, compared to conventional warm water and steam heating, it is able to maintain the temperature with a simple operation and does not require arduous maintenance.