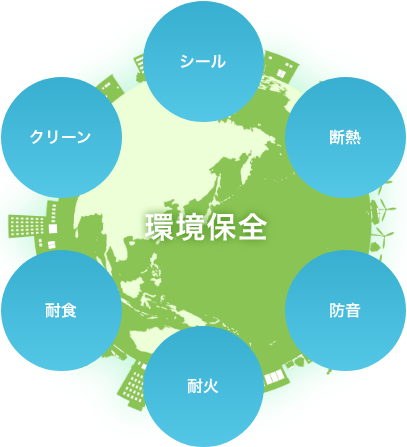

ニチアスは 「断つ・保つ」®の技術で

地球の明るい未来に貢献します

ニチアスは、「シール」「断熱」「防音」「耐火」「耐食」「クリーン」といった「断つ・保つ」®の技術を基盤とした5つの事業でさまざまな産業分野を支え、地球環境の保全に貢献しております。

各種プラント設備向けに製品やエンジニアリングを提供する「プラント向け工事・販売事業」をはじめ、基幹産業を主な市場とする「工業製品事業」、半導体産業に特化した「高機能製品事業」、自動車メーカーなどを主な客先とする「自動車部品事業」、ビルや住宅の建材を供給・施工する「建材事業」、いずれの事業もこれまでに培ってきた技術や経験を活かしながら、グローバル化を推進しています。

製品案内

Products Information

お知らせ

News

- すべて

- お知らせ

- 製品関連

- イベント

- WEBセミナー講演のお知らせ【Thermofit®(省エネ診断システム)「見える・分かる・対策できる」で見逃さない熱ロス】

- 展示会「COMNEXT 第2回次世代通信技術&ソリューション展」に出展します

- WEBセミナー講演のお知らせ【Thermofit® (省エネ診断システム)~隠れた熱ロスの発見とその対策~】

IR ニュース

IR News

会社案内

Company

サステナビリティ

Sustainability

お問い合わせ

Contact

.JPG)